Woven Fabrics

Yarn Count

• We offer counts in 10s, 20s, 30s, 40s, 50s, 60s, 80s and 2/100s, 40D, 40SF.

4 point checking & 100% checking In woven poplin

Twill flannel brushed

Cotton poly

Cotton viscose

Stretch

Viscose

modal

Oxfords

Recycle poly

quilted

Chambray

Cotton poly stretch

Sateen

Knitted Fabrics

KNITS - S/J, Rib, Pique, Honey comb, Cotton lycra , 2 Thread Fleece, Cotton poly, Cotton modal in a GSM 150 to 280. Fabric Sourcing capacity upto 10,00,000 meters per month from top mills around India.

Integrated computerized sample section with the daily output 500 pieces and some customer approach self-fit & PP sample approval. Our sample section has ability to hand any type of garments.

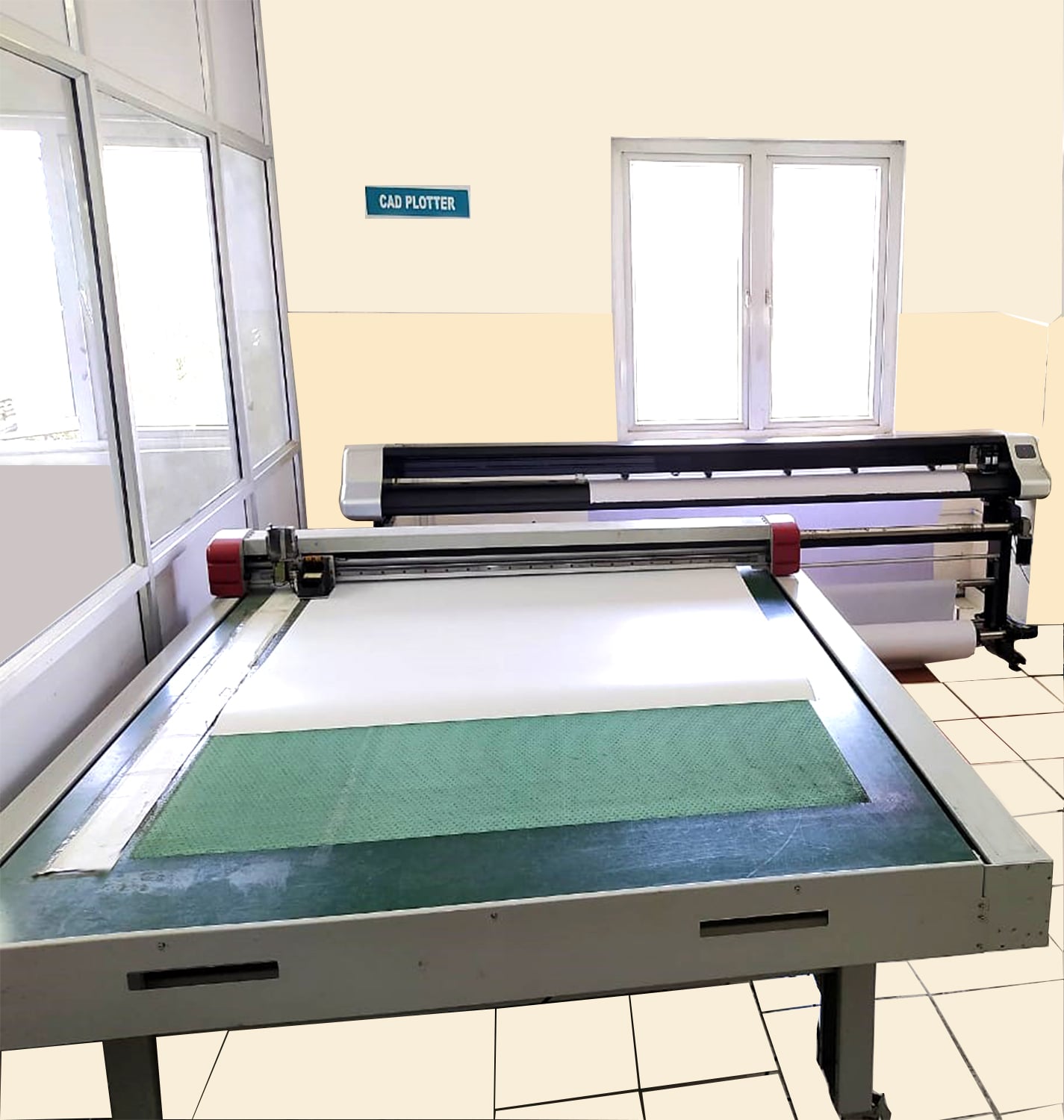

• Optitex automatic CAD machine

The key to producing fine garments lies in cutting. We have Marker Mechanism with CAD cutting systems to deliver accuracy in cuts. Our infrastructure facilitates cuts in both standards and customized size. Automated fabric spreading machines for open width and woven fabrics are also present. Our dexterous craftsmen ensure exactness in size standards as well as minimization of waste.

Our sewing division has 1000 sewing machines of Juki, Jack, Siruba, and Pegasus makes installed across streamlined production units. The division is designed to handle stitches of different types and styles. Our skilled workers are well adapted to deliver quality as well as quality. We are capable of producing 500,000 pieces a month.

Printing is a key area for leaving a lasting impression. We employ the latest technology to perfect our printing. Rotary printing systems have been installed to offer our customers a range of print options. The printing systems can print around one lakh metres/day. With customized print options available, we are able to offer value additions to our customers.

Intricate embroidery works are a value addition we provide our customers with. Our Embroidery division is equipped with 24 imported machines offering high precision and pace. The machines make it possible to design embellishments, motifs and logo designs on the garments. With the best kind of equipments in place, we are capable of delivering 11.1 million complex stiches per day.

We have adopted Total Quality Management (TQM) initiative in our processes, functioning and management. Every measure we take is a symbol of our commitment to meet international quality standards.

A quality control department is in place to make sure each step of the manufacturing process passed rigorous standards. The team monitors the quality in all our production units. Quality is controlled at every stage from style and fit approvals through size wet, pilot batch, initial, inline and final inspections. We follow AQL 1.5 to 2.5 Level quality standards (as per the buyer’s option) throughout our production units.

Washing

Washing is important to improve the marketability and texture of garments. Our washing unit is equipped with 6 washing machines and a capacity to wash 25,000 garments per day. We have multiple wash options such as silicon/stone and enzyme, bio-polish etc., besides, water is treated at both ends making it an eco-friendly one as well.

Ironing & Packing

In-house wood fired boilers provide steam at required temperatures to press and dry our garments. The garments are checked for the presence of metal using needle detector machines. We have conveyor and box systems where 100% needle detecting is done. After ensuring the garments are metal-free, packing with in-house stuffing begins. The products are well-stacked to prevent damages during transit.